Rumored Buzz on Sheroz Earthworks

Table of ContentsSheroz Earthworks Things To Know Before You Get ThisThe Main Principles Of Sheroz Earthworks Some Known Factual Statements About Sheroz Earthworks Sheroz Earthworks for DummiesThe 15-Second Trick For Sheroz Earthworks

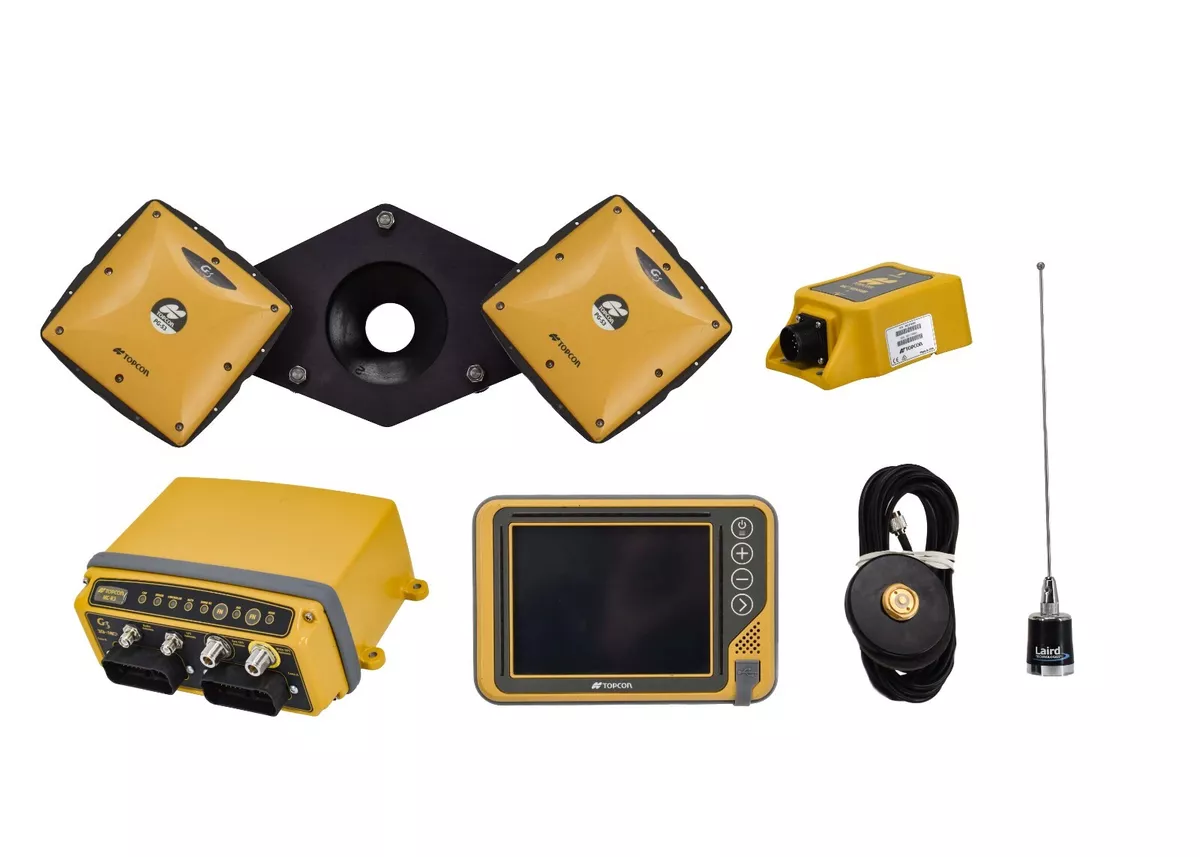

Getting the ground to simply the ideal level is no simple task. 3D equipment control systems permit automatic blade control, directing the dozer blade to specifically the ideal angle at exactly the ideal places. This system improves precision and effectiveness by a big margin. By making certain degree ground, it takes full advantage of safety and security for workers once the structure procedure starts.Scratching functions somewhat like dozing, however on a much finer and even more accurate range. While dozers press huge amounts of dust out of the method to also out the ground, scrapes go back over the location to fine-tune it. topcon laser level. Device control for scrapers features simply like for dozers, guiding the blade to just the appropriate position to achieve a perfectly level cut.

Machine control can include value to numerous agriculture tasks, including: You can make use of the technology to intuitively keep track of and map area info in genuine time, making navigating and guiding your devices less complicated than ever. Secret features include helped guiding that removes a lot of the burden from the driver, water administration, yield monitoring and camera input.

Maker control is rugged enough for hefty area use and provides the versatility to do numerous drain system applications. Attaining maximum vertical precision is vital when grading and forming land for farming. Machine control systems can handle this tough application quickly and effectively, enabling you to boost performance and reduce downtime in the field.

The Ultimate Guide To Sheroz Earthworks

Experience measurable enhancements in essential areas like machine and asset organizing, fuel usage and preventative maintenance. Boost task website safety and various other crucial procedures by enhancing precision and reliability in necessary mining procedures. Get rid of inaccurate hand-operated area dimensions and enhance reporting adaptability in your geotechnical and environmental tracking programs with these innovative data-capturing solutions.

Regardless of what the emphasis of your most current building and construction job is, you can gain from equipment control. It can refine your progressing and sharpen your digging, and it can do it all while providing you feedback on where each wanderer is on the site at any given moment. As an overseer, you can use the system software application to see the entire site simultaneously and observe every location that is being altered in genuine time.

SITECH Southwest can obtain you the maker control system you require to revolutionize your construction process (https://yoomark.com/content/home-sheroz). As a licensed Trimble dealer, we provide top-notch equipment for all the building refines listed above. Simply obtain in touch with us today to get your machine control system!.

Sheroz Earthworks Can Be Fun For Anyone

For this to work, turning lasers were established up to transfer signals that might be selected up by sensors placed on dozers or . This gave operators the basic information they required for their equipments. Yet, in comparison to modern-day equipment control, these early systems were still really restricted at giving a full and precise picture and were also often too costly or complex.

It is clear that there is a lack of fresh talent getting in the industry. Specifically, service providers have problem drawing in youths and, as a result, there are fewer drivers getting in the career. Must this trend continue, the industry will be entrusted to a lack of seasoned and reputable drivers, which means that the quality and productivity of jobs will be impacted by a considerable skills gap.

Surpassing merely providing drivers with an aesthetic overview to bucket or blade placement, automated machine control moves the blade to quality by speaking to the maker's hydraulics - trimble repair parts. Unlike with normal equipment control, automated machine control technology puts the obligation for precision and rate strongly in the hands of performance-enhancing innovation

When taking a look at the present construction landscape, it is clear that, despite its significant benefits, equipment control automation is not being adopted across all equipments at an equal price. Actually, although automation is being accepted on devices like graders and dozers, the uptake has been a lot slower for excavators, with the fostering price of automated click over here maker control on these equipments still approximated at around 10% in Europe in contrast to a rate of over 50% for dozers.

Sheroz Earthworks Can Be Fun For Everyone

Today, a rise in productivity on excavators can be kept in mind as enhanced precision and reduced over-digging being fairly easy to verify. Nevertheless, it is clear that the market now requires to reassess the requirements for excavators. With the demands for performance increasing and a lack of competent operators, building requires to accept the benefits that buying automated equipment control can bring.

If you are looking to boost your efficiency with today's innovation we are here to aid. Your existing team can be educated to execute all elements of the laid out and grab jobs of the day to day website needs in a no nonsense method.

As expected, the excavator drivers are under a tremendous pressure to deliver an optimal performance while attempting to achieve their efficiency objectives at the exact same time. That is why all type of help and renovations are a lot more than welcome regarding increased precision and ideal production. As constantly, modern technology is the secret.

The Definitive Guide for Sheroz Earthworks